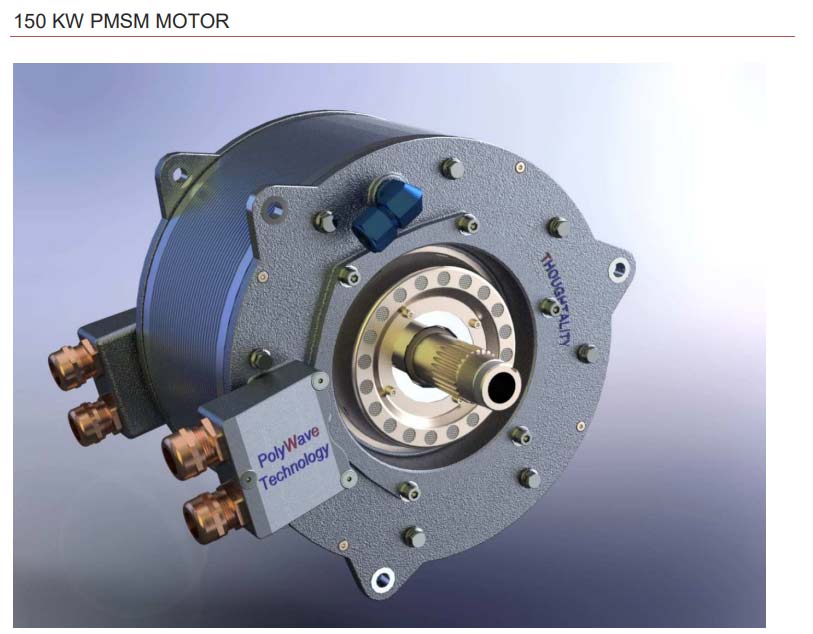

POLYWAVE MOTOR

150 KW POLYWAVE MOTOR

SPECIFICATIONS

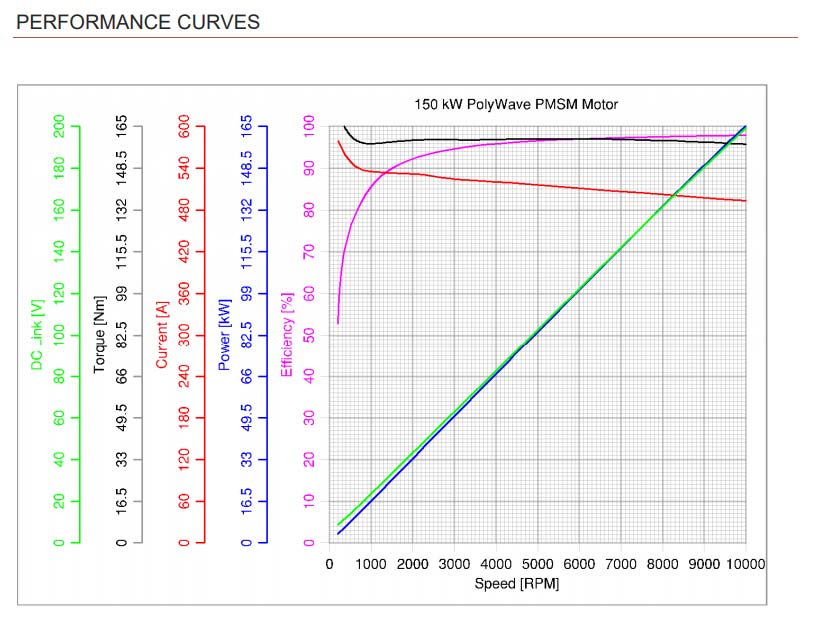

Power 150 kW

Torque 160 Nm

Speed 9000 rpm

Rated voltage 850 V

Rated current 550 A

Efficiency 98%

Current density 12.5 A/mm2

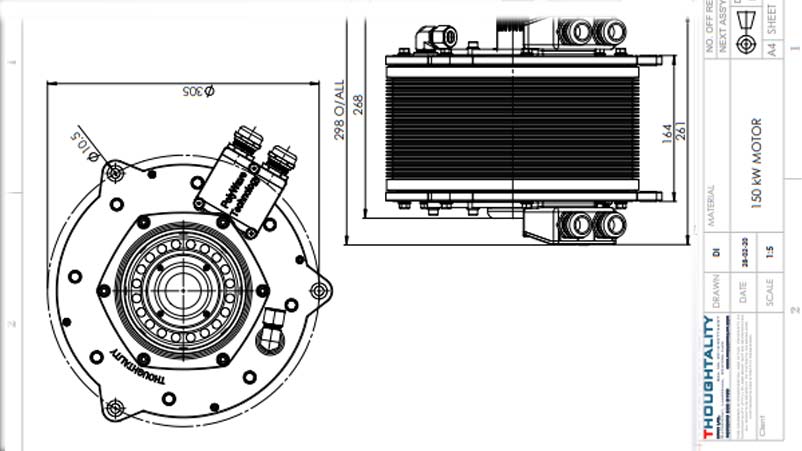

Motor weight 35 kg

Stator OD 255 mm

Cooling method Stator: oil; Rotor: air

POLYWAVE TECHNOLOGY SUMMARY

This motor is a Permanent Magnet Synchronous Motor type and uses our PolyWave Two-phase

technology. The technology is flexible to allow for other than sinusoidal wave operation with specific

advantages some of which are listed below.

- The air-gap is of constant depth and flux is uniform. (Unlike sinusoidal flux distribution, the airgap is better utilised with full flux).

- The square-wave drive configuration has very simple Power Electronics, therefore cheaper,

lighter and low part count for reliability and minimum or no maintenance. - This technology has built in simple pick-up coils giving instantaneous speed and infinite position

signals. (Not need for resolvers or hall sensors. Cheaper, less part count, less maintenance,

more reliability.) - All phases are energised 100% of rotation unlike in BLDC motors but as in 3-phase PMSM

motors. - This technology has zero cogging. (Better quality torque).

- Motor or generator stator windings are extremely compact with minimum end windings. (Less

copper). - Gravimetric and volumetric power and torque densities are comparable and in cases superior to

existing, high-end, state of the art sinusoidal driven, three-phase Permanent Magnet

Synchronous Motors. - The two-phase configuration is markedly simpler in construction and operation than current

technology. - In the 2-phase alternator configuration the output voltage may be rectified with simple, passive

semiconductors (diodes) to give a high-quality, ripple-free DC current. - Armature windings are of the concentric type which are simple to mass produce.

- In a 3-phase alternator mode the output is high quality sinusoidal 3-phase current. This is not

possible with existing turbo generators, windmills or hydro driven alternators. - The torque output is high quality, ripple-free, on par with high-end sinusoid driven motors.