NEW MAGNET-LESS TECHNOLOGY

MOTORS AND ALTERNATORS

PolyWave Power technology incorporates bipolar induction motors and alternators that are simpler and cheaper (up to 60% with increasing size) to manufacture than state of the art machines (SRM, BLDC, Homo-polar, PM and Inductance machines). This radically new topology has the following features:

- No permanent magnets IE5 efficiency and higher

- No slots in either rotor or stator therefore zero slot harmonics

- No slip rings or brushes

- Static field excitation (No windings on rotor)

- Efficiency on par and higher with high end state of the art machines

- Torque quality on par with high end state of the art machines

- Superior cooling to existing technologies (high gravimetric and volumetric power density)

- A very large open bore is possible resulting in a high torque, light weight machine

- Simple two-phase Power Electronics for motors (no electronics for alternators)

PWP technology offers motors of the synchronous type with field control resulting in high efficiency and control flexibility.

PWP technology offers alternators for 1500 rpm and 3000 rpm turbine driven units with no slip rings or magnets. The output is high quality sinusoidal 3-phase current. Up to 50% lighter with increasing size.

PWP alternators are also suitable for slow speed, direct driven wind turbines with either a 3-phase or a high quality, ripple-free DC output with either passive semi-conductor rectification or switched rectification ready for inverting to 3-phase.

PWP topology has simple external armature windings suited for optimum cooling by either air or liquid.

Field poles may be driven to saturation (therefore stable, large air-gaps are possible) without affecting the quality of the output waveform.

A PWP based hybrid-drive, where a prime-mover (such as an IC engine or turbine) driven PWP alternator drives a remote PWP motor, produces a drive train of high efficiency and control flexibility. Only the low current field coils (motor and/or alternator) need to be regulated by relatively in-expensive PED (power electronics drive) for complete control over a wide range of power and speeds. This avoids high power electronics (as is the case in the state of art). This translates into highly reliable aerospace, marine and vehicle drives that will continue to function in a controllable manner even in a case of PED failure. This, combined with PWP simplicity, low cost and cooling advantages makes for a very attractive hybrid drive solution, hard to beat by exiting technology.

Licenses and IP rights are negotiable in all classes.

Summary

This new motor and generator technology is simpler and cheaper than state-of-the-art machines, has increased reliability, simpler electronics and an infinite marketing shelf life using standard widely available materials; it is difficult to imagine a better marketing edge in the global economy.

Dragan Ignjatovic info@thoughtality.com

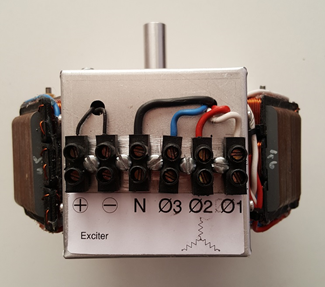

Prototype of two stage, three-phase alternator (above) with an oscilloscope scan of the output waveform (below). Zero harmonics with not a single electronic component; just iron and copper.

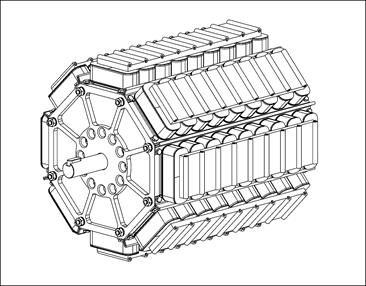

Eight stage, two-phase motor

Prototype terminal connections